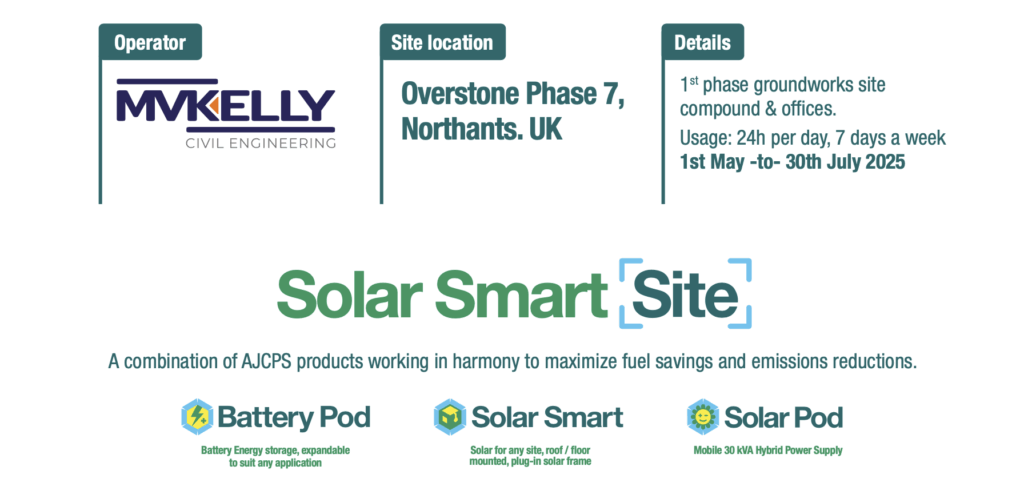

13 Aug AJC Power Solutions – Solar Smart Site. Case Study / Fuel Efficiency Report

Project Outline

The aim of this project is to transform how early-phase construction sites are powered. These sites (particularly groundwork phases) have traditionally relied on diesel generators. This project sets out to reduce that dependency by introducing low-emission hybrid energy systems as the new standard.

MV Kelly, one of the UK’s leading groundwork contractors, has used a fleet of AJC Power Solutions SolarPod units across its sites for over two years, consistently reducing fuel use and emissions. Overstone Phase 7 in Northamptonshire (for David Wilson Homes) is the first MV Kelly site to deploy all core AJC Power Solutions technologies— SolarPod, BatteryPod, and SolarSmart Frames—in a fully integrated setup, designed to maximise carbon and fuel savings.

The site aims to prove that an entire temporary construction compound can be net- zero, reliably powered by solar and battery storage with an HVO generator used only for backup. All hand tools on-site are electric, all heavy plant on site is fuelled by HVO, with emissions offset through carbon credits.

By combining AJCPS technologies into one coordinated system, the project reduces fossil fuel use, CO2 emissions, and air and noise pollution—while maintaining performance. The wider goal is to create a scalable, repeatable model for cleaner, smarter construction.

Project Achievements

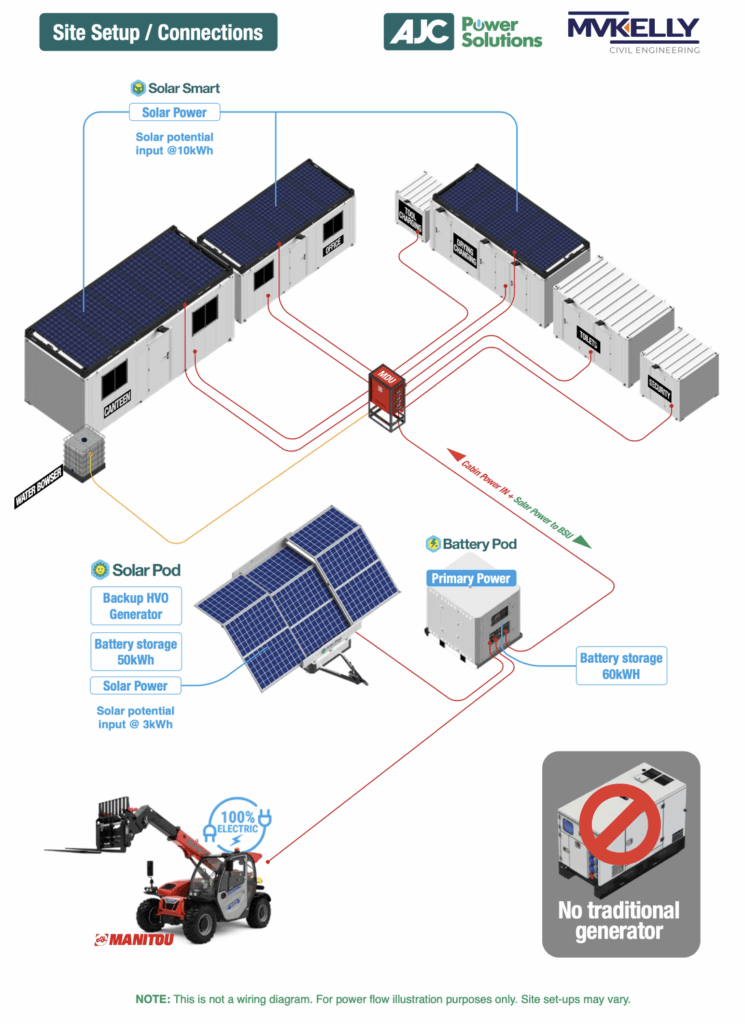

Successful deployment of a fully integrated, low-emission power system on an active groundwork construction site. At the Overstone site, MV Kelly utilised the complete range of AJC Power Solutions technologies—including the SolarPod, BatteryPod, and SolarSmart solar frames – to power an off-grid site compound.

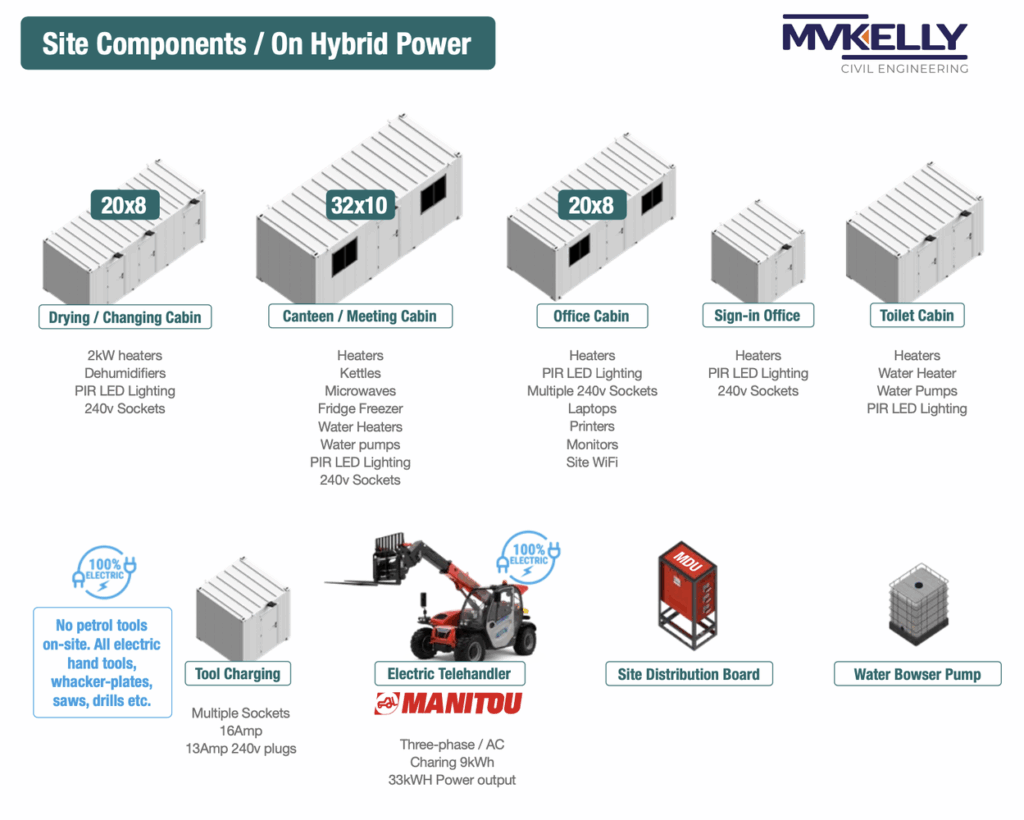

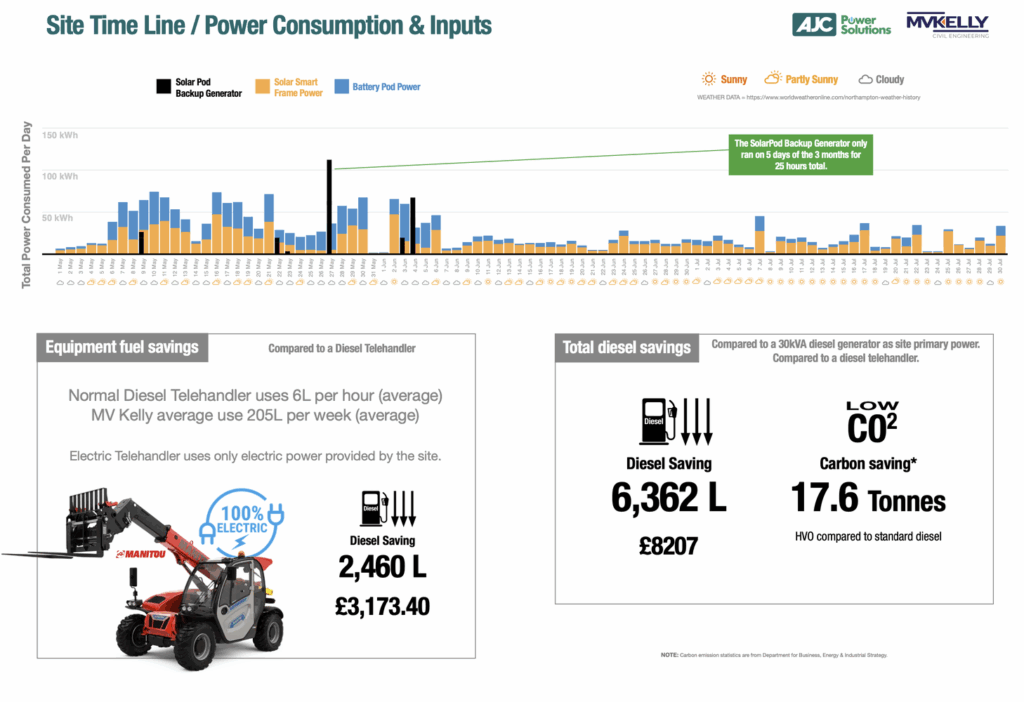

The setup delivered uninterrupted energy to multiple high-demand units, including welfare cabins, site offices, a tool charging station, and an electric Manitou MRT telehandler. Crucially, the system ran with the BatteryPod as the primary source of power, supported

by solar input from the SolarPod and SolarSmart frames. The HVO diesel generator in the SolarPod was only used as a backup, drastically reducing overall runtime. The site ran 24-7, with peak power demands during working hours, night-time power use from ancillary office power and telehandler charging.

This integrated hybrid setup is the first of its kind within MV Kelly’s portfolio. It proves that even high-demand, construction compounds can operate efficiently with minimal environmental impact. The success of this trial sets a precedent for wider rollout across MV Kelly’s UK sites.

Project Details

This project involved the full deployment of a complete AJC hybrid power solution to sustainably run an off-grid groundwork construction site, reducing reliance on diesel generators. MV Kelly partnered with AJC Power Solutions to install an integrated solar, battery, and smart energy management system at its Overstone Phase 7 site (For David Wilson Homes).

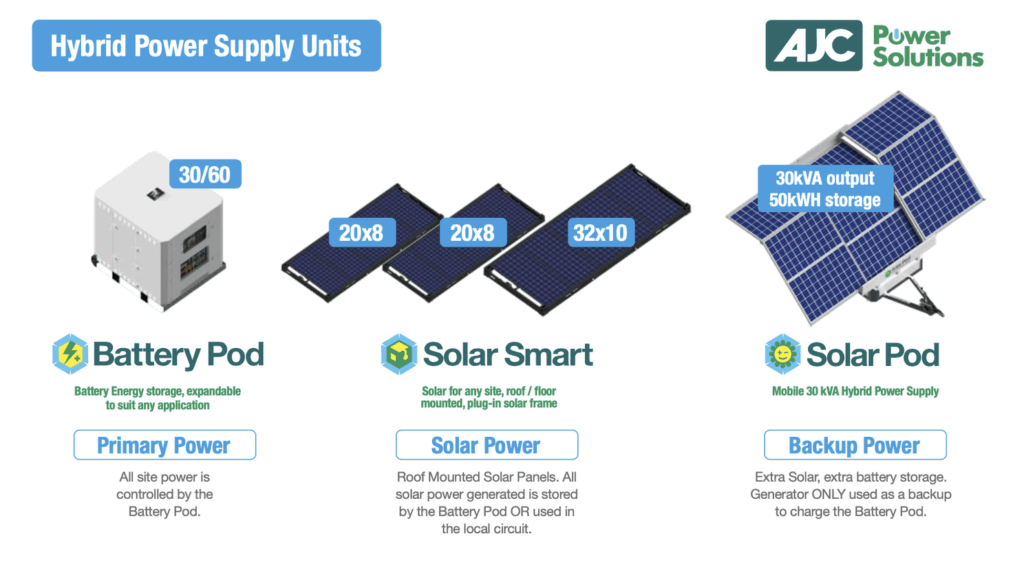

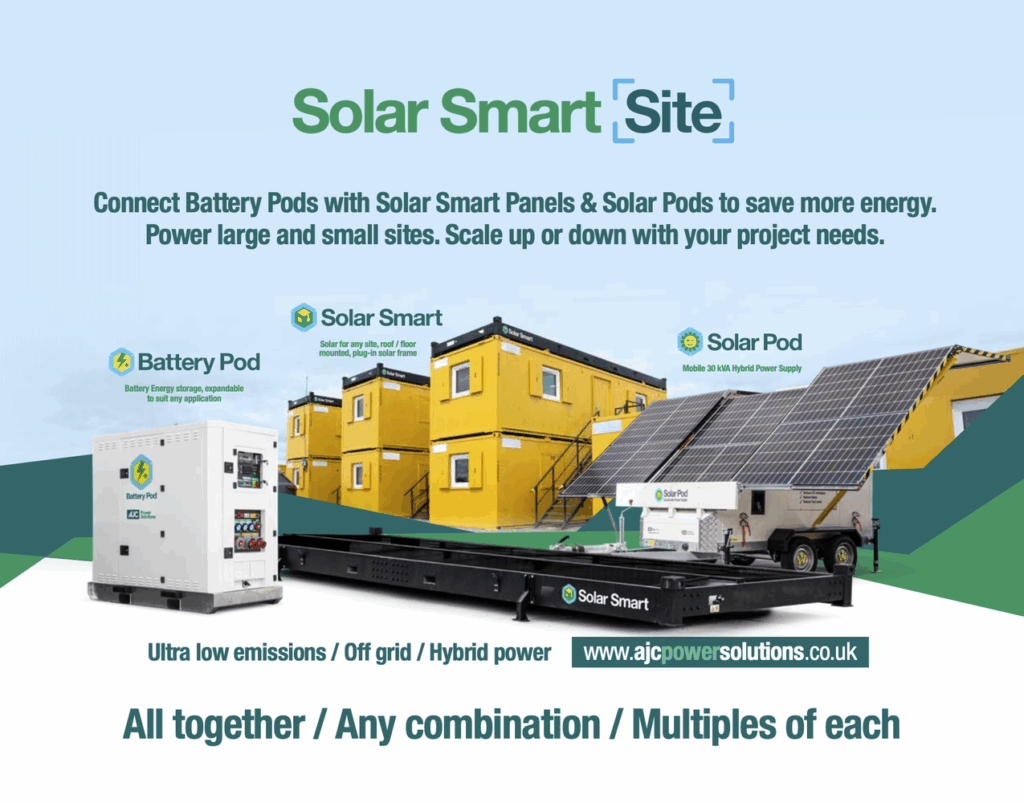

The setup included:

- AJC SolarPod 50kW Solar hybrid generator

- X3 AJC SolarSmart Frames

- AJC BatteryPod 30/60 Site-wide smart distribution system.

These powered the site’s facilities:

- UK’s first electric Manitou MT625e telehandler

- Drying-Changing Cabin

- 20×8 Canteen Meeting Room

- 32×10 Office Cabin

- 20×8 Security Office

- Toilet Cabin Tool

- Charging Cabin (All small tools on-site are battery powered)

- Water Bowser

While MV Kelly had already invested in a fleet of (15x) SolarPod units over the last two years, this site marked the first time the entire range of AJC Power Solutions technologies was combined to maximise efficiency, emissions savings, and renewable energy use. The project was intended to prove that even the earliest, most demanding phase of construction (typically powered entirely by diesel) could operate with minimal fossil fuel use and reduced environmental impact – and achieve Net-Zero status.

The cost of this initiative was covered directly by MV Kelly through its internal investment in sustainable technologies. No external grants or subsidies were used. All equipment used was purchased as part of MV Kelly’s plant and site fleet strategy (including £30K of electric hand tools), meaning that assets deployed at Overstone Phase 7 will continue to be reused across other sites. This investment approach reflects MV Kelly’s long-term environmental planning, balancing net zero sustainability goals with economic practicality.

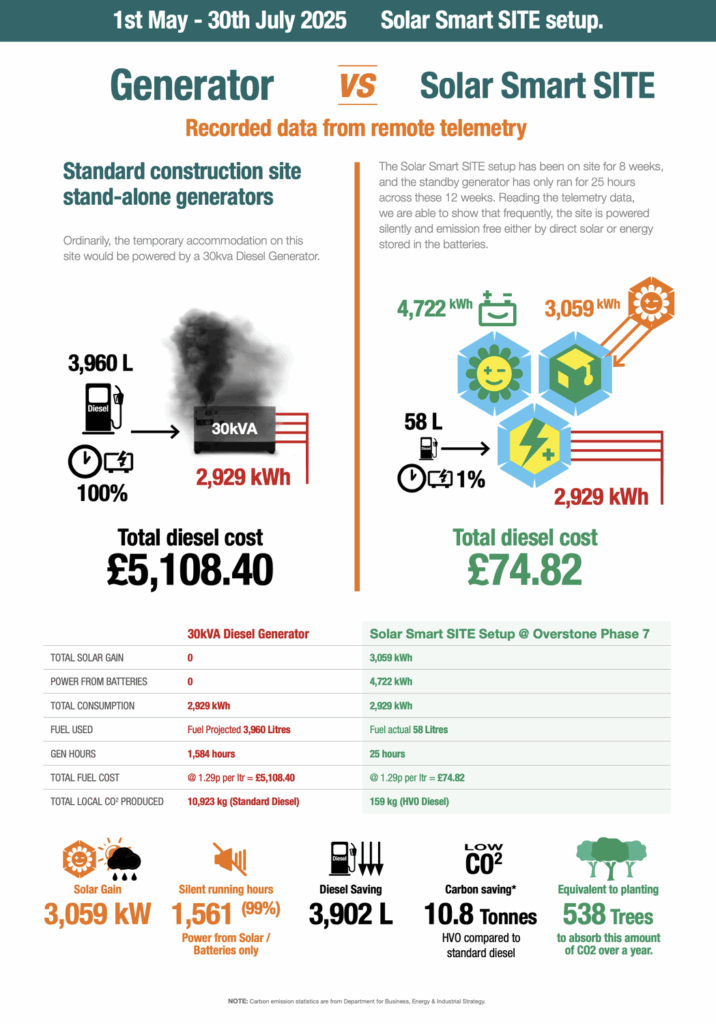

In terms of measurable achievements, the project delivered significant gains across environmental, operational, and economic metrics. During 3 months of operation, the site achieved:

- 3,059 kWh of solar energy generated

- 4,722 kWh of battery energy consumed

- 58 litres of HVO fuel used (by backup SolarPod Generator)

- 99% reduction in generator runtime*

- 10.8 tonnes CO2e emissions saved*

* Compared to a traditional Generator-only setup 30kVA. Using standard Diesel compared with HVO diesel

While HVO (Hydrotreated Vegetable Oil) was still used to fuel backup generation and machinery across the site, it was the only fuel used, ensuring the site’s fossil-free status. All HVO-related emissions were fully offset by MVKelly, making the site officially carbon neutral.

Operational noise and local air pollution were also greatly reduced. Economically, reduced diesel use and generator wear meant cost savings and lower servicing demands. These improvements strongly align with the principles of sustainable development: cleaner, quieter, and lower-impact infrastructure that continues to support productivity and worker welfare.

MV Kelly benefited from reduced operating costs and strengthened environmental performance. Site workers enjoyed a quieter, cleaner working environment and improved welfare conditions. AJC Power Solutions gained valuable real-world performance data to support future innovation. Local communities experienced less disruption from noise and fumes typical of diesel generators. The wider construction industry stands to benefit through a proven, replicable model that supports the transition to low-carbon site operations.

There are clear long-term benefits from this project. All equipment used is mobile, trailer- towable, and redeployable, allowing it to support future MV Kelly sites and maximise its lifetime environmental savings. The success of this project has prompted MV Kelly to plan similar deployments across its UK operations, forming a long-term strategy for powering off-grid compounds more sustainably. The project also shows that hybrid systems can support electric plant such as telehandlers, opening the door to more electrification across the sector.

AJC innovation was central to the success of this trial. Although MV Kelly had experience with SolarPods, this project brought together multiple renewable and smart technologies into a single integrated power system. The BatteryPod was used as the primary power source, intelligently recharged by the SolarPod and SolarSmart Frames. HVO Generator (in the SolarPod) use was minimised and intelligently controlled by the system. The inclusion of a large electric plant machine – powered entirely off-grid – added another layer of complexity and innovation. Very few UK groundwork sites have run electrified plant equipment using an entirely hybrid off-grid system.

The model developed in this project is highly transferable to other contractors, infrastructure firms, events companies, or utility providers operating remote or temporary sites. The AJC system is modular, scalable, and simple to deploy, requiring no complex installation or infrastructure. Any organisation currently relying on diesel generators for compound power can adopt this approach, lowering fuel bills and emissions while improving working conditions.

The project also provided valuable learning opportunities. It confirmed that battery-first power architecture delivers much greater fuel savings than generator-first models. It demonstrated the practicality of powering large electric machinery from stored solar energy, even on remote sites without mains access. As a result, MV Kelly is now actively reviewing its site setup strategy to favour integrated hybrid power across all groundwork operations. AJC Power Solutions is using the results to guide further product development, focusing on load management, system integration, and real-time remote monitoring to drive even greater efficiencies.

Since launching the first SolarPod in 2018, AJC Power Solutions has continually evolved its technology to meet the growing demands of low-carbon construction. By 2020, the company introduced the first integrated setup combining SolarPod, BatteryPod, and SolarSmart Frames, a significant step toward off-grid autonomy. Each generation has brought major improvements in design, control systems, ease of deployment, and energy efficiency. The Overstone Phase 7 project represents the latest advancement: smarter controls, faster installation, and greater power output with minimal user input. Today’s systems are plug-and-play, scalable, and require little training, making sustainable site power more accessible than ever.

Sorry, the comment form is closed at this time.